Guaranteed Best Price

Shop with Confidence knowing you've got the best price

Guaranteed Best Price

Shop with Confidence knowing you've got the best price

Y-axis Rotary Chuck (ARC) for AlgoLaser

Product Description

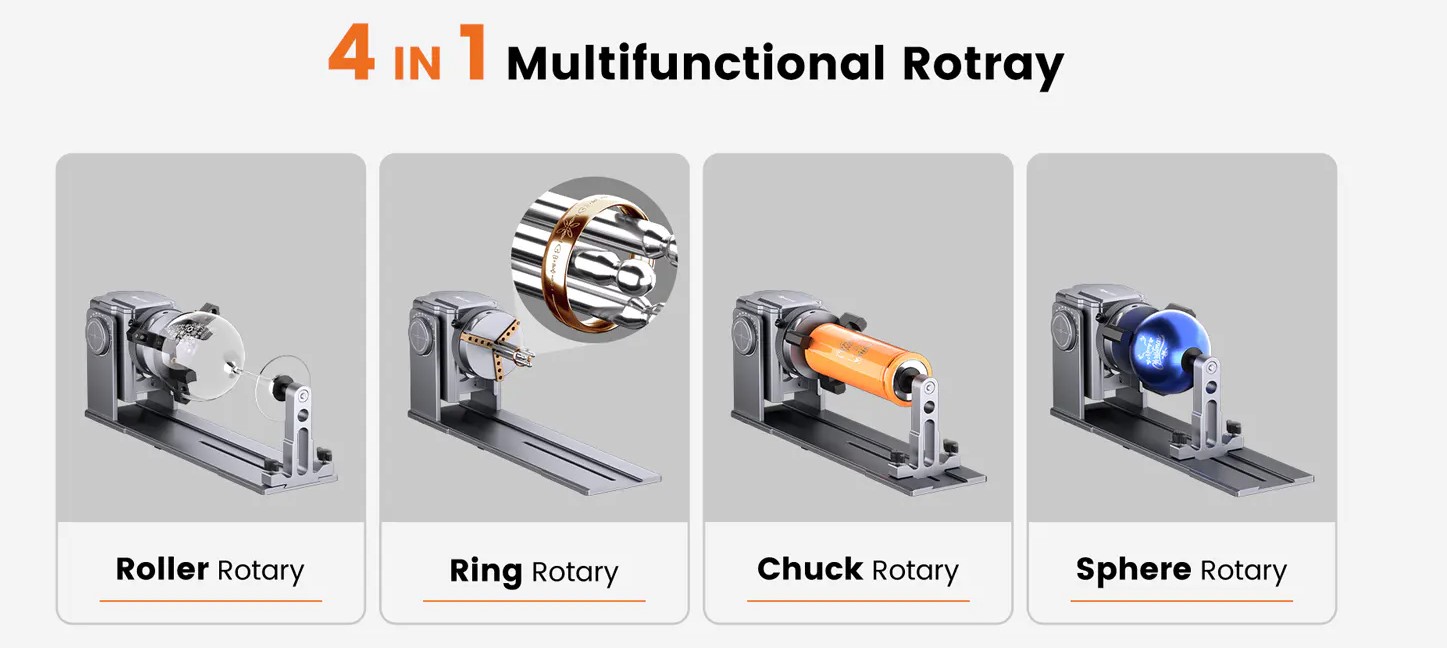

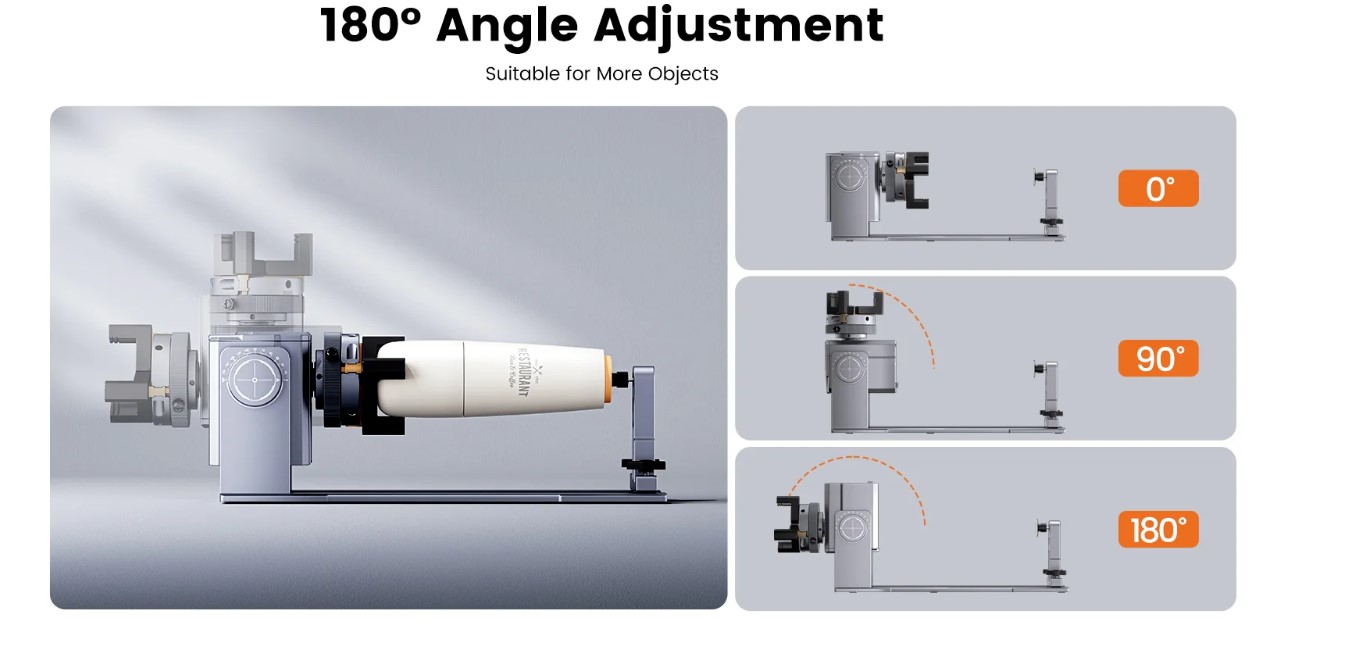

This is the rotary roller and chuck for the Algolaser machines. The chuck increases the circular sizes and provides more capability than a standard rotary roller.

FAQ

1. What shapes of objects can ARC be used to engrave?

Applicable to cylindrical, spherical, ring-shaped, and conical objects.

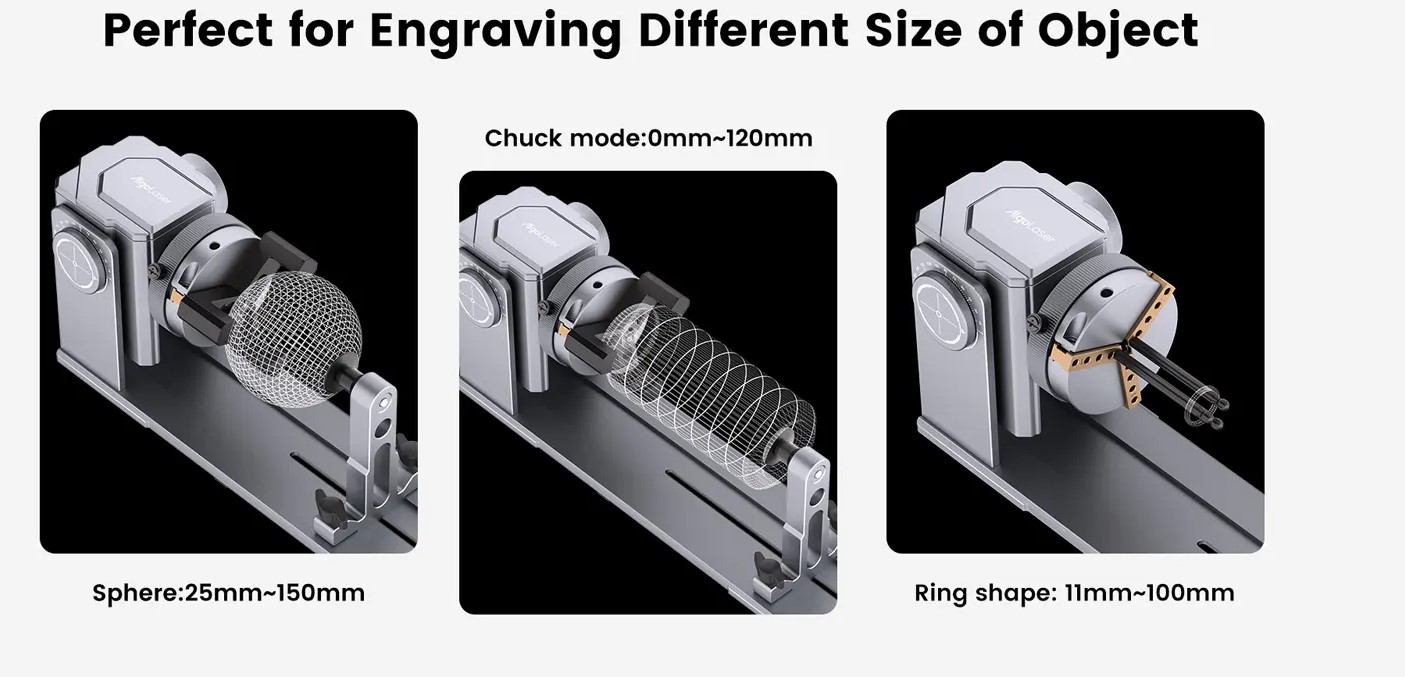

2. How big an object can ARC engraving?

The maximum supported diameters are: Cylinders: 1-120mm, Spherical objects: 25-150mm, Rings: 11-100mm.

The length of the object depends on the direct placement distance from the side, and is generally applicable to normal objects under this diameter. For special objects, please bring photos and ask technical support.

3. How to use ARC?

If you purchase an AlgoOS product, please click Settings-Machine-Working Mode-ARC and enter the relevant parameters for the object to be engraved.

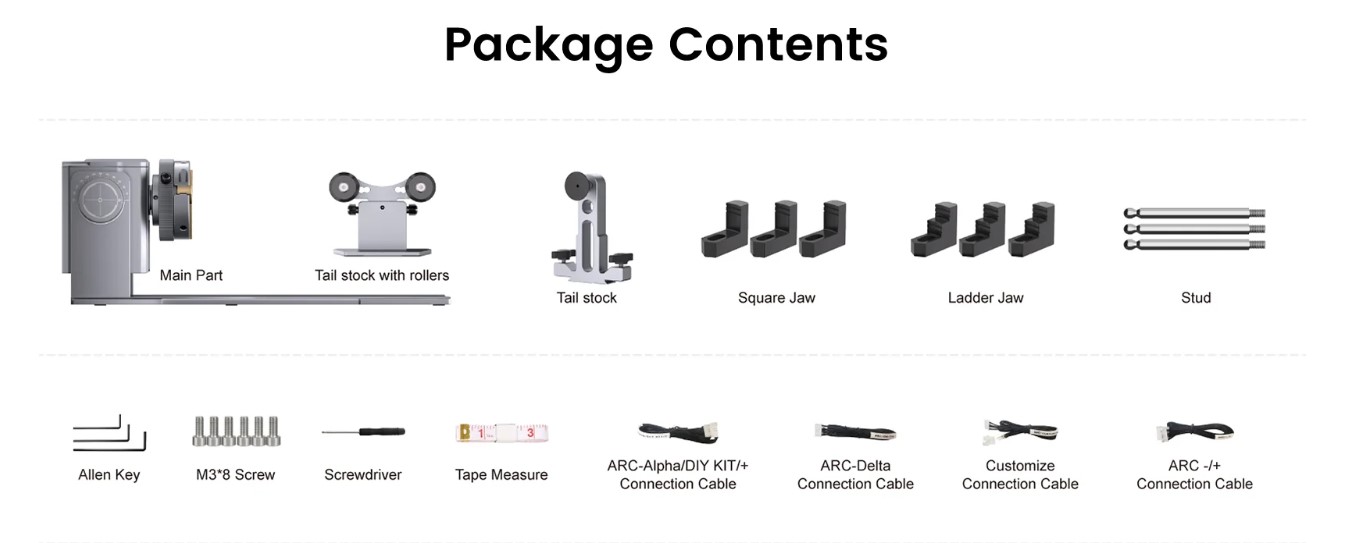

Refer to the instructions to connect the cables and place them, and then you can start engraving. For other machines, refer to the tutorials in the instructions and modify the code to adapt the relevant work.

4. What should I pay attention to when engraving?

Before carving, make sure the carving surface is kept level, the jaws are locked, and use a test piece to test parameters and carving before carving, to prevent damage to the carving.

Please note: Locally Stocked. Available for Immediate Shipping